To start you need a passion, to finish you need a discipline.

show email

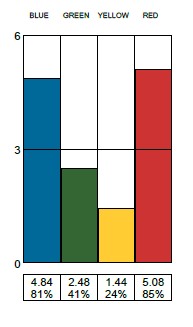

It combines the dominant traits of the Fiery Red color energy and the Cool Blue color energy.

Individuals with this profile are often strong-willed, assertive, and results-oriented (Fiery Red), while also being analytical, organized, and detail-oriented (Cool Blue).

They are likely to display a direct and disciplined approach to tasks and have a natural inclination towards driving change and improvement.